BIC’s Commitment to Lighter Safety

BIC is serious about safety.

We have been making BIC Lighters since 1973. With consumer safety in mind, we developed and meet / exceed the most rigorous safety and quality standards so you can trust that any BIC lighter is high performing, convenient and safe.

Each of our 6 million lighters produced worldwide daily undergoes more than 50 quality and safety checks during the manufacturing process.

ASTM Voluntary Lighter

Safety Standards*

The following are some lighter safety standards recommended by ASTM International, these tests are most closely related to accidental fires and injuries. Many low-quality (and often less expensive lighters) failed at least one of these tests, compared to BIC which meets or exceeds all voluntary standards.

Flame Extinguishing Time

After a user removes their finger from the lighter, there should not be any exposed flame within 2 seconds, and any flame that might continue below the hood or windscreen should fully extinguish within another 2 seconds. *All BIC lighters extinguish in less than half a second.

Spitting & Sputtering

The condition where non-evaporated or liquid fuel escapes from the lighter producing a shower of burning liquid droplets that separate from the main flame. *BIC’s fixed flame lighter design does not create spitting or sputtering.

drop test

Every lighter should be able to withstand three separate 5-foot drops without fuel reservoir fragmentation, sustained self-ignition or gas escape (leakage) exceeding 15 milligrams per minute. *BIC lighters are routinely drop tested from a height of 10 feet or more and withstand the requirements.

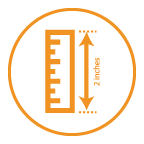

Resistance to Continuous Burn

If a lighter is lit for two minutes or more, the highest flame height should be two inches if held vertically, without any issues of components continuing to burn, or the valve rupturing / coming apart. *All BIC lighters meet these requirements.

Flame Extinguishing Time

Flame Extinguishing Time

After a user removes their finger from the lighter, there should not be any exposed flame within 2 seconds, and any flame that might continue below the hood or windscreen should fully extinguish within another 2 seconds. <em>*All BIC lighters extinguish in less than half a second.</em>

Flame height

Flame height should not exceed 2-inches for non-adjustable lighters or 4.75-inches for adjustable lighters (adjustable lighters are lighters which enable the user to change or “adjust” the flame height). *BIC lighters have a consistent flame that are well within safety standards.

Flaring

There should be no greater than 2-inches of variation in flame height from the steady state flame condition. In other words, the flame should not flare up unexpectedly to a greater height. *BIC’s fixed flame lighter design does not create flaring.

Volumetric Displacement

Liquid portion of fuel should not exceed 85% of the fuel reservoir capacity, to allow for some expansion within the body of the lighter in hotter weather conditions (as one example). *BIC’s automated manufacturing process ensures the fuel doesn’t exceed 85% of the fuel reservoir capacity.

Resistance to High Temperature

Every lighter should be able to withstand 149-degrees Fahrenheit for 4 hours without gas escape (leakage) exceeding 15 milligrams per minute. *BIC lighters are routinely tested and withstand 167°F for 8 hours.

*Do NOT attempt to test a lighter at home!

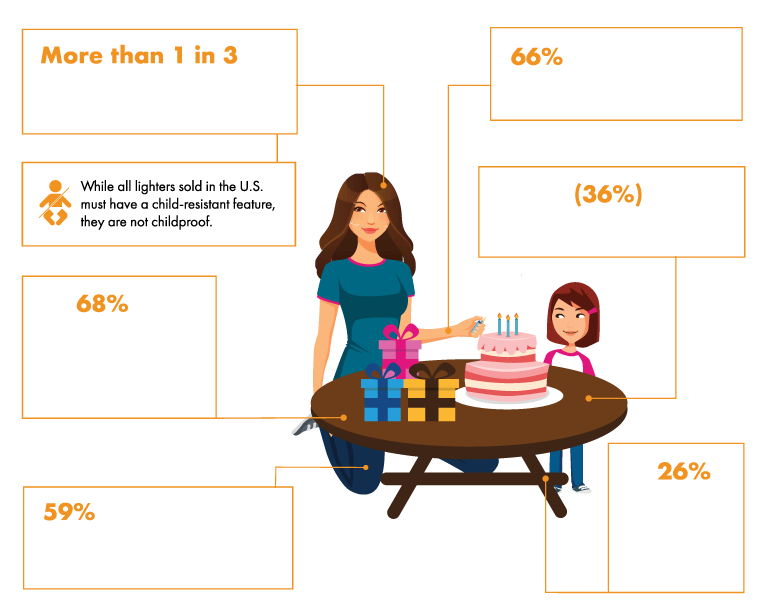

Since introducing the child-resistant lighter and launching proactive public education efforts, the U.S. has seen declines in the following areas:

- Number of serious fires and deaths / injuries from fires

- Number of structure fires started by children

- Children starting fires that involve lighters and matches while playing

However, two factors have threatened to reverse the progress of the last quarter century:

All Lighters Are Not Created Equal.

Low-quality (non-BIC) imported lighters are currently flooding the U.S. market with more than 300 million exports entering the U.S. in 2017 alone. BIC’s most recent internal testing found that as many as 70% percent of non-BIC lighters tested in the U.S. failed voluntary safety standards set forth by ASTM International, meaning they can lead to serious fires, damages or injuries.

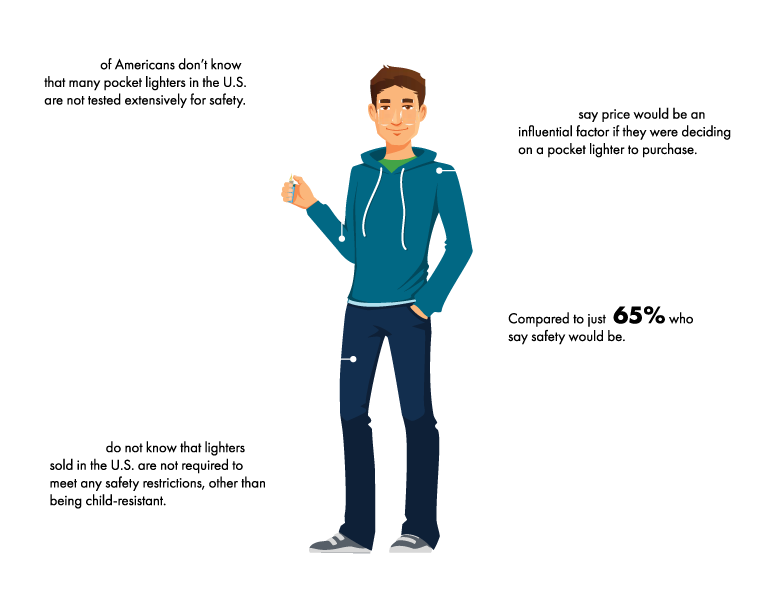

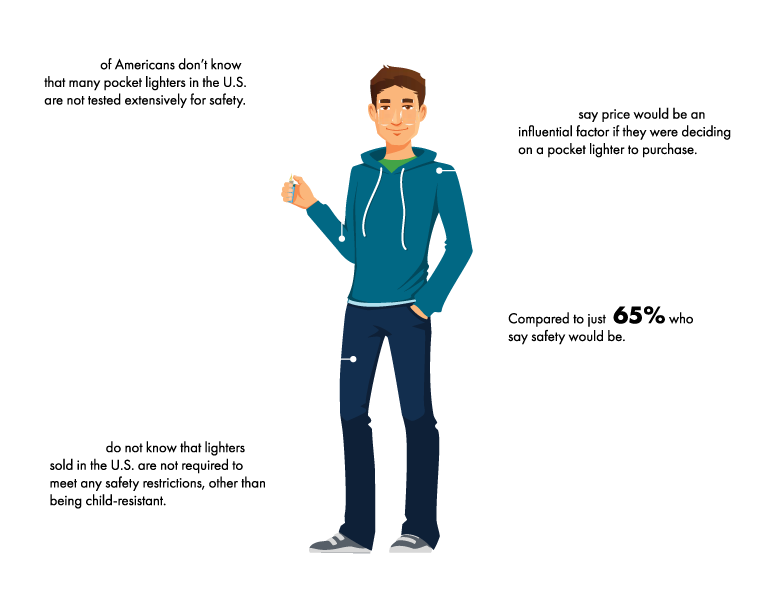

A Lack of Consumer Awareness and Action around Lighter Safety.

A March 2019 survey by BIC and Harris Poll found that many Americans don’t understand lighter safety and standards, therefore are not making fully-informed purchase decisions or taking appropriate precaution for lighter safety in their homes and daily lives.

Understanding lighter safety standards

So what should you know about lighter safety standards? First, all lighters sold in the U.S. must be child- resistant, but that does not mean they are childproof. A child-resistant product means it is more difficult to operate, but some young children may have the dexterity to do so.

Second, this feature is the only requirement issued by the CSPC. ASTM International one of the world’s largest standards-developing organizations, sets forth key voluntary lighter safety standards. While BIC meets or exceeds each test, most competitor lighters failed at least one standard in internal BIC testing.

Bic® Pocket Lighters

What goes into a Bic® Lighter?

We weren’t the first to create fire (you’ve got us there, cavemen). But we invented the coolest way to make a flame: the iconic BIC® Pocket Lighter. Here’s a look at our lighter’s inner workings, no x-ray glasses required.

Guard

Safety guard added over the sparkwheel on all BIC® child-resistant lighters.

Sparkwheel

When the sparkwheel, which is made of serrated hardened steel wire, is rotated with sufficient speed and force, it creates a spark.

Hood

Steel. Acts as a windshield and offers heat protection.

Fork

Along with the jet and fork spring, these components control the opening and closing of gas coming from the valve. Releasing the fork automatically stops the flow of gas from the valve.

Flint

Supplies material for the sparks. The flint spring applies pressure to the flint to generate sparks.

Fork Spring

Along with the jet and fork, these components control the opening and closing of gas coming from the valve.

Jet

Along with the fork and fork spring, these components control the opening and closing of gas coming from the valve. The jet/globe seal subassembly is quality checked using a sophisticated camera vision system.

Flint Spring

Feeds flint onto sparkwheel as flint wears. The flint spring applies pressure to the flint to generate sparks.

Valve

The subassembly regulates fuel flow and releases a constant level of fuel, permitting a constant flame of predetermined height.

Body

This is plastic; ultrasonically welded with the base. The body, base and seal ball constitute the gas reservoir.

Base

This is plastic; ultrasonically welded with the body. The body, base and seal ball constitute the gas reservoir.

Ball

Seals the gas reservoir after it is filled.

About BIC

About BIC Contact us

Contact us