A more environmentally friendly version

of the iconic BIC® Classic® lighter

This BIC® Ecolutions™ Lighter integrates all the best sustainable development options BIC® has identified so far with scientific and research laboratories, without compromising the performance, quality and safety of the product.

What’s new with BIC® Ecolutions™?

* Bio-attribution means that a quantity of raw material of natural origin is attributed to a finished product according to the mass balance principle. To produce bio-attributed Plastic, BIC® supplier uses a production system where biomass raw material is mixed with fossil raw material. They are then indistinguishable. The mass balance principle allows the volume of bio-attributed Plastic purchased by BIC® to be "attributed" to BIC® Ecolutions™ lighter (through a documented system certified by an independent body, ISCC - International Sustainability & Carbon Certification) and to prove that it is actually produced by BIC®. This attribution system ensures a significant reduction of the carbon footprint. Through this purchasing method, BIC® contributes to the transition from the use of fossil-based raw materials to renewable alternatives.

“ECOLUTIONS”

BRAND

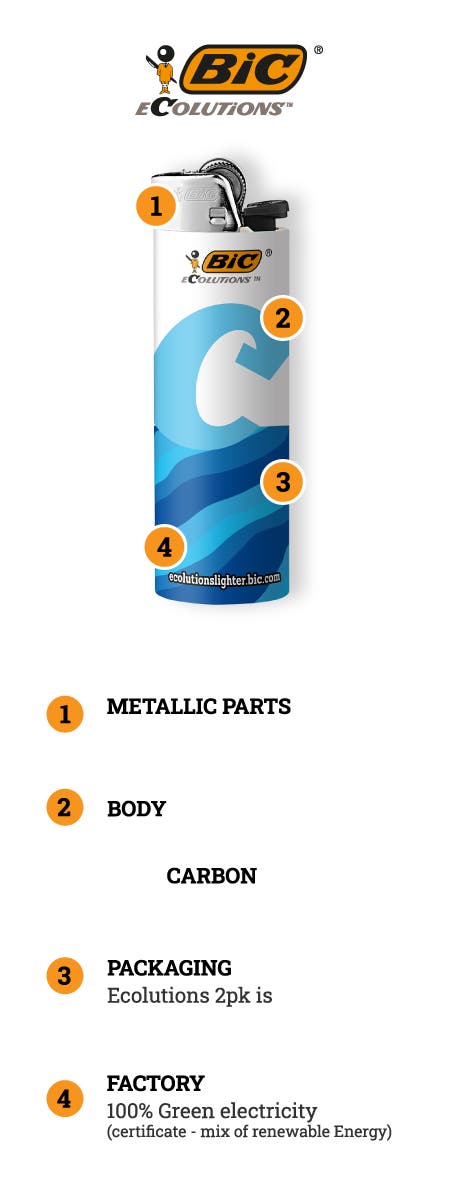

How did we reduce the carbon footprint

of BIC® Ecolutions™?

1

We evaluated

BIC® Maxi Classic’s

Carbon Footprint

First, we asked a specialized firm (EVEA) to conduct a Life Cycle Assessment of the BIC® Maxi Classic® lighter, which measured its carbon footprint at each stage of its life, from the extraction of raw materials to the disposal of the used product.

3

We completed

CO2 reduction

efforts

Then, we implemented CO2 reduction efforts and developed BIC® Ecolutions™. Again, we asked a specialized firm (EVEA) to conduct a Life Cycle Assessment of the BIC® Ecolutions™ Lighter. This allowed us to measure the CO2 emission reductions compared to the BIC® Maxi Classic® lighter, due to recycled or biosourced raw materials.

5

We decided to go furtherby offsetting 30% of carbon emissions

Then, we decided to go even further by offsetting 30% of carbon emissions of each lighter through certified programs: The so-called carbon offsetting approach consists, after having sought to reduce its CO2 emissions, of financing projects that reduce and sequester CO2 in order to compensate for its own emissions (for example, reforestation programs). The carbon offsetting programs selected by BIC® and its climate and energy advisor are certified by Verra Registry System or Gold Standard and consist of climate projects (mostly agroforestry).

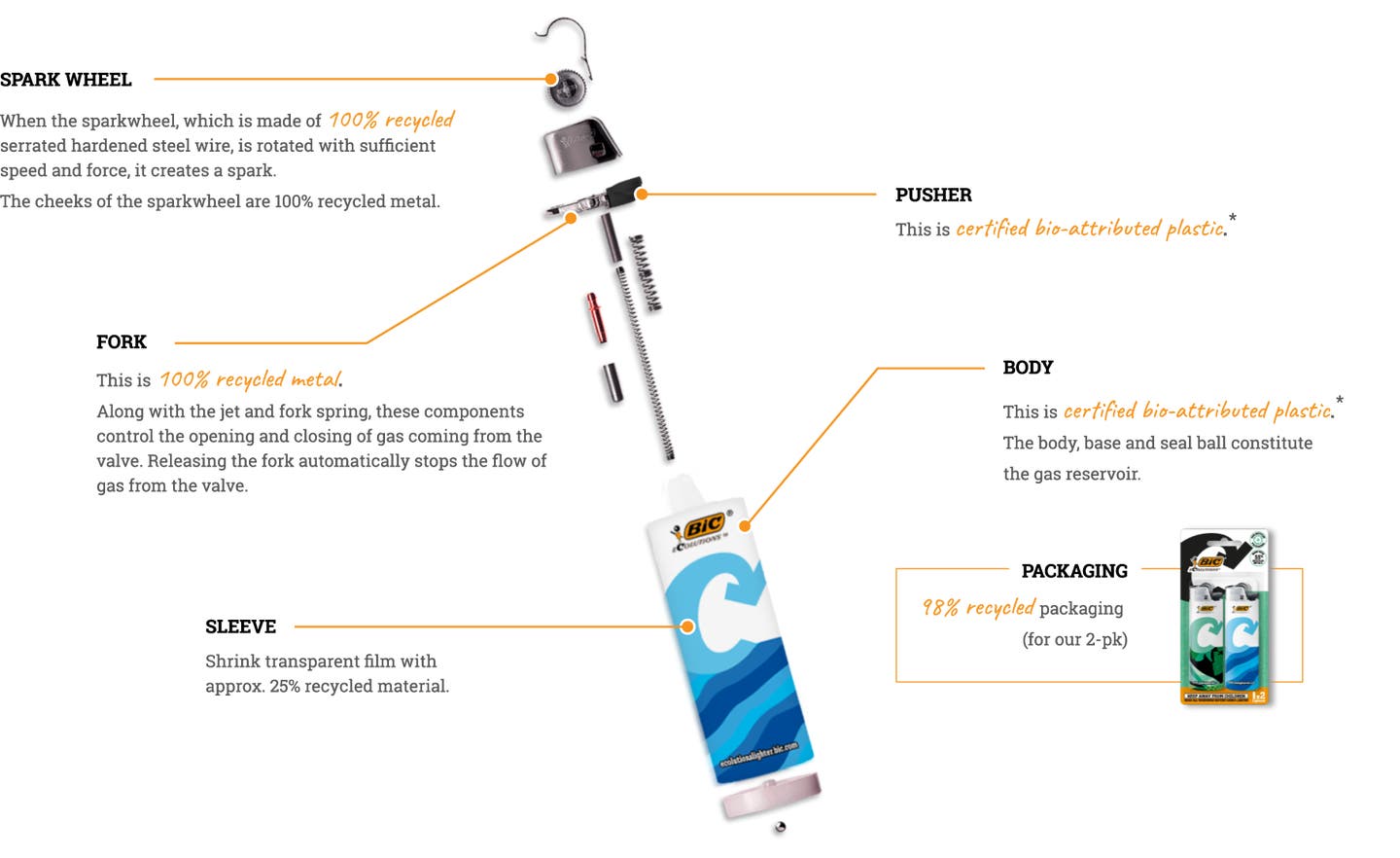

What’s goes into a BIC® Ecolutions™ Lighter?

Same Quality & Safety, Same performance

With up to 3,000 lights but with many improvements

(representing less than 8g of raw material per 1,000 lights)

* Bio-attribution means that a quantity of raw material of natural origin is attributed to a finished product according to the mass balance principle. To produce bio-attributed Plastic, BIC® supplier uses a production system where biomass raw material is mixed with fossil raw material. They are then indistinguishable. The mass balance principle allows the volume of bio-attributed Plastic purchased by BIC® to be "attributed" to BIC® Ecolutions™ lighter (through a documented system certified by an independent body, ISCC - International Sustainability & Carbon Certification) and to prove that it is actually produced by BIC®. This attribution system ensures a significant reduction of the carbon footprint. Through this purchasing method, BIC® contributes to the transition from the use of fossil-based raw materials to renewable alternatives.

About BIC

About BIC Contact us

Contact us